Custom Hearing Protection | Musicians & Industrial Ear Plugs

Custom hearing protection provides precise noise reduction whilst preserving sound quality essential for work performance, communication safety, and recreational enjoyment. Unlike generic foam plugs offering crude across-the-board sound blocking, custom-moulded ear plugs deliver measured attenuation matching specific noise exposure patterns whilst maintaining clarity for speech, music, or situational awareness. Understanding custom protection benefits, available types, fitting processes, and appropriate applications helps you select hearing protection that genuinely protects long-term hearing health without compromising essential listening.

Professional assessment determining your specific noise exposure patterns, protection requirements, and usage contexts ensures custom ear plugs match genuine needs rather than generic solutions potentially unsuitable for your circumstances.

Why Custom Hearing Protection Matters

Generic disposable ear plugs provide inconsistent protection highly dependent on proper insertion. Studies show most users achieve 5-15 dB less protection than rated values due to improper insertion, and some achieve almost no protection despite believing they're protected.

Custom-moulded ear plugs matching your individual ear canal anatomy create reliable seals achieving rated protection levels consistently without requiring perfect insertion technique. Sound quality preservation proves impossible with foam plugs that muffle all frequencies. Custom protection employs acoustic filters providing frequency-specific attenuation, reducing harmful noise whilst maintaining speech intelligibility and sound quality.

Communication requirements in noisy work environments often force workers to remove protection to hear colleagues or alarms. Custom filtered protection allows communication while still blocking harmful noise. Long-term comfort ensures consistent daily use. Custom moulds eliminate irritation, pressure points, and discomfort making foam plugs impractical for extended periods.

Custom Protection for Musicians

Musicians require noise reduction without sound distortion. Standard plugs are unsuitable because they destroy tonal balance. Flat attenuation maintains natural sound rather than muffling specific frequencies. Musicians' plugs typically reduce all frequencies equally by 9 dB, 15 dB, or 25 dB depending on filters.

Multiple filter options allow different protection for rehearsal vs performance. Interchangeable filters add versatility. Preserved sound awareness allows hearing your instrument, monitoring others, and communicating with conductors. Performers who speak to audiences benefit from natural-sounding speech rather than the muffled tones caused by heavy foam plugs.

Instrument-specific needs affect ideal attenuation: drummers often need heavy protection, strings moderate, brass and vocalists vary, and sound engineers require balance for accurate mixing.

Industrial and Workplace Protection

Workplace noise requiring hearing conservation programmes demands reliable protection workers will consistently wear. Custom protection ensures regulatory compliance by reliably achieving safe attenuation levels under WHS legislation. Filtered industrial plugs allow communication with colleagues, hearing alarms, and maintaining safety without removing protection.

All-day comfort encourages workers to keep protection in for full shifts. Industrial hearing testing often reveals preventable hearing loss in workers using generic plugs inconsistently. Custom protection helps prevent this. Custom moulds also provide durability in harsh environments, resisting oils, sweat, and repeated handling.

Recreational and Sports Applications

Shooting and hunting require extremely high attenuation or active electronic plugs blocking gunshots while allowing normal sound. Motorsports generate sustained loud engine and wind noise. Custom plugs protect hearing during long events or rides.

Woodworking and power tools create intermittent but intense noise; custom plugs provide convenient, comfortable protection. Swimming and water sports use specialised custom plugs preventing water entry while allowing some sound transmission. Aviation enthusiasts and private pilots benefit from custom aviation plugs preserving communication while reducing aircraft noise.

Custom Moulding Process

Effective custom protection begins with accurate impressions of your ear canals. Otoscopic examination checks for wax, infections, perforations, or anatomical variations that influence mould creation. Impression material options include silicone or foam, chosen based on canal sensitivity and intended plug type.

A protective dam is placed deep in the ear canal before injecting impression material. The canal is filled with silicone which sets within minutes, capturing detailed anatomy. Removal involves gentle twisting to break the seal without discomfort. Laboratories use these impressions to manufacture precise custom moulds.

Types of Custom Hearing Protection

Solid custom moulds offer maximum attenuation (25-30 dB) suitable for very loud environments or heavy industrial use. Filtered musician plugs reduce sound evenly across frequencies (typically 9, 15, or 25 dB). Communication plugs allow speech frequencies through while blocking machinery noise.

Electronic ANR plugs reduce low-frequency noise electronically while preserving important sounds. Swim plugs prevent water entry and differ from noise protection designs. Sleep plugs use soft materials and shallow fitting for comfort during side-sleeping.

Filter Selection and Attenuation Levels

9 dB filters offer light protection for moderate noise or acoustic performances. 15 dB filters provide balanced protection suitable for most musicians, many workplaces, power tools, and lawn equipment. 25 dB filters suit extremely loud environments such as amplified music, drumming, industrial machinery, or clubs.

Professional noise measurement helps determine exact attenuation needs. Both under-protection and over-protection can be harmful; correct filter choice balances safety and awareness.

Proper Use and Maintenance

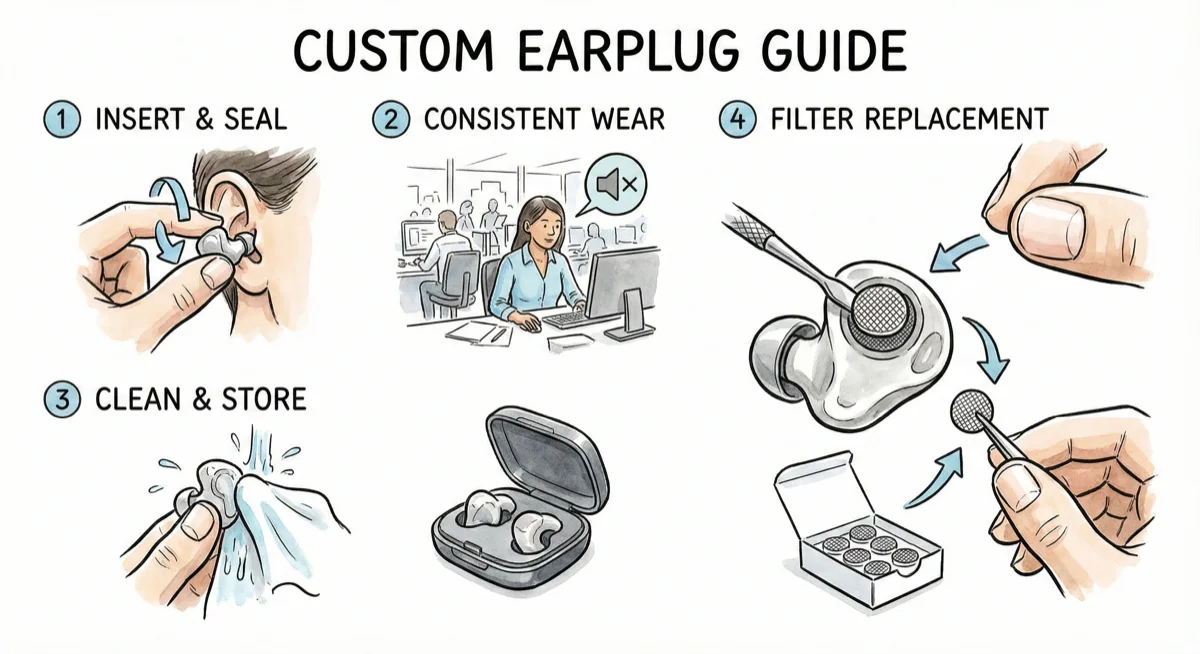

Insertion typically involves gentle twisting to seat moulds fully. Seal verification ensures proper attenuation; cupping ears helps detect whether the seal is complete. Protection is only effective when plugs are actually worn, so consistent use is essential.

Daily cleaning with mild soap and water preserves hygiene and material integrity. Storing plugs in protective cases prevents physical damage. Filters require periodic replacement to maintain accurate attenuation.

Lifespan and Replacement Needs

Custom plugs generally last 3-5 years with proper care. Material deterioration such as cracking, hardening, or shrinkage eventually affects seal and comfort. Ear canal changes from ageing or weight fluctuations may require new impressions.

Filters in musician or communication plugs may degrade sooner and need replacement. Physical damage indicates immediate need for replacement.

Selecting Appropriate Custom Protection

Selecting the right custom protection requires understanding your specific environments, noise exposures, and communication needs. Professional consultation ensures advice tailored to your usage patterns and safety requirements.

Noise assessments often reveal unexpected exposure levels influencing optimal filter selection. Frequent users benefit most from custom options, though even occasional users in extreme noise may require custom solutions. Budget considerations matter, but hearing preservation offers far greater value than the initial investment.